Semiconductor industry

Semiconductor industry

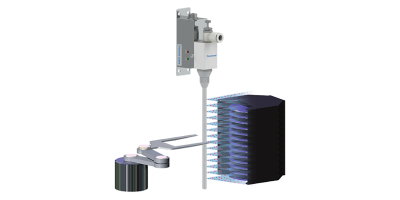

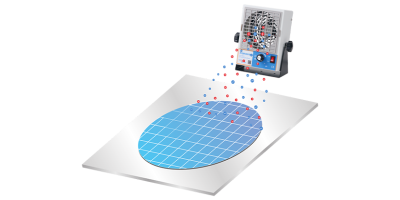

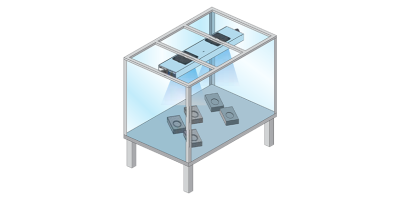

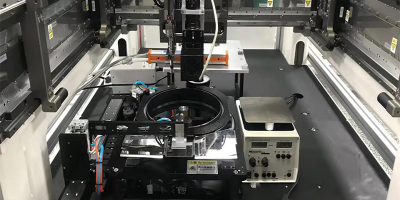

Electrostatic adsorption of dust has a great impact on the microelectronics industry. in the production of modem large-scaleintegrated circuits (LSl), the line spacing of the chips is very smal. lf it produces electrostatic adsorption of a few to tens ofmicrons of dust is obvious. A diameter of a few microns of dust adsorption on the chip, can cause dozens of core wireinsulation between the strength of the reduction, so that the chip leakage current increases, the service ife is shortened, andeven guickly caused by a short circuit so that the chip is damaged. Due to electrostatic adsorption of dust. especially forphotoelectric devices (CCD, LED, photovoltaic cells, etc.), its conversion eficiency wil be greatly reduced. As shown in Figure1-10 for the comparison of dust particle size and IC chip spacing. Acid, alkal, silicon and other microparticles adsorbed on thechip, can also cause chip corrosion.

How Can We Help Your Business?

Quickly review your requirement and deliver professional technical solutions efficiently!We listen and we care your needs,Our people will get in touch with you by email and phone calls in 24 hours.

Phone number:+86 19879326646

Email address: linqiusong0914@gmail.com

Our hours:9 am – 6 am (EST)