With its new ionization technology, the ion rod has set a new standard in the industry, and its performance meets the strict requirements of the electronics industry for the residual voltage of the ionizer in the EPA electrostatic discharge protection zone to be less than +35V, the aluminum alloy shell is suitable for use in cleanrooms due to its oxidation resistance and low particle emissions and the light contour of the aluminum color ensures a good visual integration of the clean room.

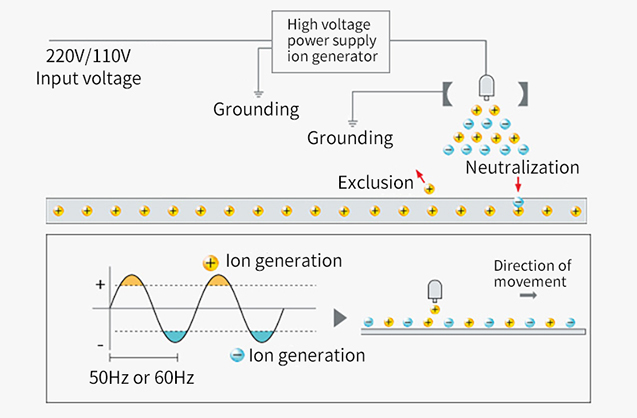

When a high voltage is applied to the ion needle in an alternating current mode, the electric field generated by the ion needle ionizes the surrounding air and ionizes the air into positive and negative ions, which are attracted by ions of opposite polarity to neutralize the static electricity, and the remaining ions quickly disappear into the atmosphere.

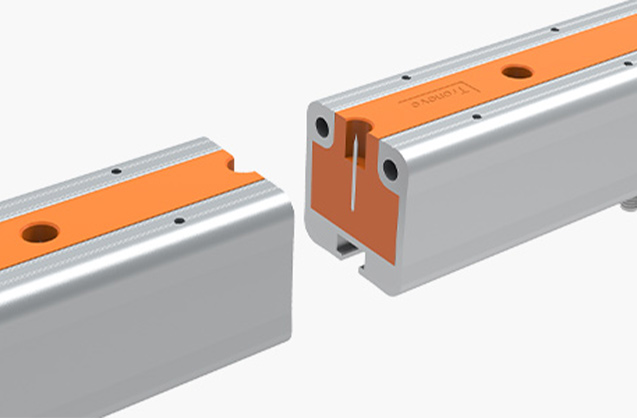

We all know that the gas entering the ion rod needs to be dried and cleaned to avoid the water vapor and oil in the gas source from enteringthe ion rod, but many times the product failure is caused by the uncleanuse of gas, and the design of electrical separation can effectively solve this problem, and the separate gas path will not affect the electronic part.

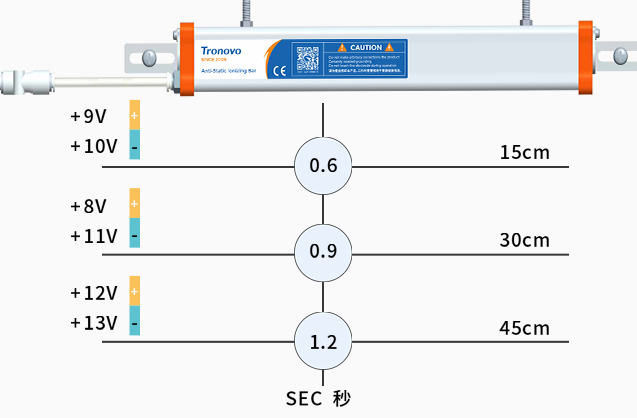

The speed of static elimination depends on the number of ions necessary for the static eliminator to be released to the surface of a live object in a given time. To increase the total number of ions, it is necessary to increase the ion generation capacity (the number of ions generated per unit of time).

Quickly review your requirement and deliver professional technical solutions efficiently!We listen and we care your needs,Our people will get in touch with you by email and phone calls in 24 hours.

Phone number:+86 19879326646

Email address: linqiusong0914@gmail.com

Our hours:9 am – 6 am (EST)