Automotive

Automotive

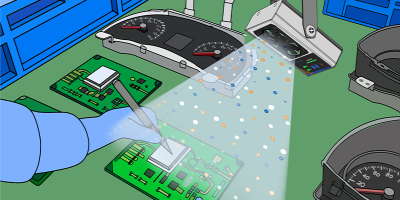

The most common problem is the dust adsorption caused by static electricity, which affects the next step of the process, and electrostatic shock during the installation of the instrument table.

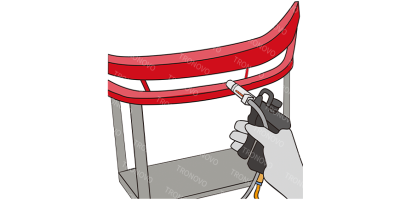

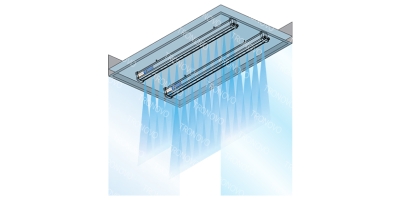

Ensure that the body and plastic parts in the spraying before the elimination of static electricity, to avoid the adsorption of dust caused by the spraying effect is not good and lead to rework, a counter-attack, is tens of thousands of hundreds of thousands of dollars in costs.

1. Before body coating, electrostatic dust adsorption

2.Handling bumper electrostatic dust adsorption

3.Static dust adsorption when handling the front panel

4. Electrostatic discharge and electrostatic dust adsorption when installing the instrument panel.

After painting the front bar there are part…

Through several aspects of understanding…

The Eyre Rotary Blow Nozzle combines adva…

The Animal Punch Type Ionizing Gun is ideal…

How Can We Help Your Business?

Quickly review your requirement and deliver professional technical solutions efficiently!We listen and we care your needs,Our people will get in touch with you by email and phone calls in 24 hours.

Phone number:+86 19879326646

Email address: linqiusong0914@gmail.com

Our hours:9 am – 6 am (EST)