Bottle assembly line dust removal and electrostatic removal case

Bottle assembly line dust removal and electrostatic removal case

In modern industrial production, as a packaging container, the cleanliness and electrostatic protection of the bottle are very important. Especially in the cosmetics, food, pharmaceutical and other industries, the dust and static electricity inside the bottle will not only affect the quality and appearance of the product, but also pose a potential threat to the health of consumers. There fore. how to efficiently and safely realize the removal of dust and static electricity on the bottle assembly line has become the focus of many manufacturers.

Problem description:

During the production process, the dust and impurities are adsorbed on the bottle due to static electricity, which affects the quality of the product.

Solution:

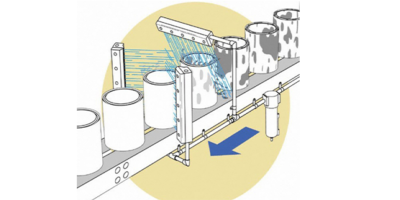

Install the ion air knife on the production line, and use the high-speed and efficient ion air flow to blowoff the dust and foreign matter on the product.

Conclusion:

By installing the ion air knife system, it not only success fully realized the comprehensive removal of fine dust on the bottle body, but also efficiently eliminated the accumulated static electricity in the production process, giving the bottle a new look of cleanliness and safety. This 1 innovative applications significantly improve product quality, reduce the rate of defects caused by dust or static electricity, and optimize the overall hygiene standards of the production environment. Customer feedback shows that since the introduction of this dust removal and static elimination program, the product return rate has dropped significantly and customer satisfaction has continued to rise.